Saving The Planet With Algal Oil

Algal Oil

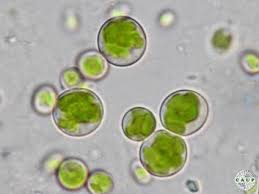

What is Algal Oil? It is Green Oil made using Blue-Green Algae (carefully selected and/or cultured for good yields), and with the use of Greenhouse Gases from power stations or smelters and other producers of large quantities of Greenhouse Gases), sunlight, water (can be sewerage, polluted water, salty water or otherwise non-potable), and waste land, and you can produce quite large amounts of oil, that can be refined to diesel or petrol or ethanol and is a Greenhouse friendly fuel to use in existing car, truck and bus fleets.

Please note: - This material is taken from a now archive website around 2009-2011. Then Oil prices were exploding, and technology was developed to produce Algal Oil (or Green Oil). Then Oil prices plunged, and interest was lost in the technology. However, it could NOW be used to economically reduce pollution in power production, especially reducing greenhouses gases. This would enable extension of current power production, economically, whilst new technology is being developed, tested and installed.

It could also allow older technology in power production to remain economical, whilst also reducing pollution and greenhouse gases. For many people the cost of cooking, heating and cooling, is a huge burden, especially for larger families

----------------------------------------

Algal Oil - The Answer To Global Warming

We are told by the various bodies advising on Global Warming that time is running out and that enemy of the Planet is our vast armada of cars, trucks, aircraft and out huge numbers of coal burning power stations, smelters and similar. But what if we could turn Global Warming around by turning the enemy into a friend.What if we can turn around Global Warming by actually using the Greenhouses Gases that pour into the atmosphere into the fuels that we need, and prevent the huge rise in oil prices that will follow the inevitable end of the economic winter we are currently facing?

There are many ways of making fuel. We can turn coal into oil (messy and expensive), we can use more gas (but one day we will run out), we can turn our corn and sugar and rice into ethanol, and the poor can grow hungry. No there are more sensible ways, and this site will over the next few months show a huge range of sensible solutions to our fuel needs. Oil can be made using blue-green algae (algal oil) and we can use many crops that are not for food, which can be grown on marginal land and with a minimum of water.

Start with the first article, CSIRO in Australia has found a bacteria that can turn forest thinnings, green garden waste, waste timber, waste cardboard and paper into bio-oil. Three Cheers for Science. Then progress as we go to Algal Oil Bio-reactors turning greenhouse gases from dirty coal stations into green oil. If the USA just made their diesel that way, they would cut the greenhouse gas emissions from their power plants by 56%.

......................................................

Algae as biofuel `in five years'

Edition: 1 - State

Section: Features, pg. 045

Section: Features, pg. 045

Energy

A COMMERCIAL alternative to diesel using biofuel made from algae will be developed within five years, the* South Australian Research and Development Institute forecasts.

Research is expected to begin at SARDI's new Aquatic Sciences plant atWest Beach next year, facility manager Eric Capelle said.

Researchers from around Australia will apply to use the facility and a committee will select those who may use it, although SARDI is the most likely main user.

The* research will be scaled up to a much larger demonstration plant in 2009-10.

Dr Capelle said the need for a clean alternative to mineral and fossil fuels was urgent, with Australians consuming more than 14 billion litres of diesel each year.

``The use of micro-algae has been identified because it has high oil-producing capabilities and an ability to thrive in saline or nutrient-loaded water resources, sunny environments and on marginal lands,'' Dr Capelle said.

The $5 million project will be used for research into micro-algae as a viable alternative feedstock for biofuels.

Dr Capelle said the high-tech infrastructure would allow existing lab-scale results to be validated at a pilot and demonstration scale.

``This is a major step forward in fully commercialising the much anticipated technology,'' Dr Capelle said.

``The potential of micro-algae as a renewable biofuel source is an exciting alternative to existing sources.

``It produces at least 30-times more oil per hectare than crop-based fuels, it is a non-food fuel resource and it consumes the greenhouse gas CO2 to grow and multiply.''

Dr Capelle said the use of algae to produce fuels was one long-term solution to the world's declining oil reserves.

``To make it commercially viable we need to improve the efficiency of algae production and oil extraction from the algae,'' he said.

``The use of algae has advantages including the fact that CO2 from power plants and breweries can be used to lower their carbon footprint.''

Dr Capelle said the main challenge was to develop a species of algae that produced enough oil.

``South Australia is a good place to grow micro-algae because there is plenty of sunlight and a lot of opportunities where saline water can be used and a plant could be built close to power plants,” he said.

The SARDI Biofuels group project is supported by the National Collaborative Research Infrastructure Strategy with state and federal funding.

------------------------------------------------------------------------

Source: Advertiser, The (Adelaide), MAR 25, 2008

''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''Last Update: Thursday, July 20, 2006. 7:48pm (AEST)

Micro-algae could provide alternative fuel

South Australia's Research and Development Institute (SARDI) hopes to turn micro-algae into an alternative fuel as part of a million-dollar research program.

SARDI says the organisms are an ideal source of biodiesel because they contain lots of oil and can grow year-round.

The Federal Government is partly funding the three-year program, which costs nearly $1 million.

SARDI spokesman Kevin Williams says the first challenge is to find the best type of algae.

"We'll be starting to select micro-algae from the wild, bring them back to the lab, evaluate growth rates and oil production and at the end of 3 years we hope to have some idea of growth and take that up to pilot scale production," he said.

Dr Williams says algae could be used to power cars in the future.

"Micro-algae have been shown in the past to produce up to 30 times more oil per unit land area, so we're hoping to achieve growth rates in Australia and create economic feedstock for biodiesel production," he said.

..........................................................................

Proposed Algae Equipment Manufacturers and Supply Channel Partner Presentations – April 2009

Algae is a source of biomass that can produce many types of biofuels, including biodiesel, ethanol, biocrude, jet fuel, and renewable diesel. Algae is a renewable fuel feedstock, does not affect the food channel and consumes C02. The byproduct biomass is used in cosmetics, pharmaceuticals, bio-plastics, and organic fertilizer. The National Algae Association, the first national trade association for the algae biofuels industry, brings algae companies and algae researchers from the US and around the world to exchange information to overcome technological hurdles.

The Department of Energy projects in its Energy Information Administration/Short-Term Energy Outlook - January 2009 that US petroleum consumption will be 19.12 million barrels per day in 2009, increasing to 19.28 million barrels per day in 2010. This is down from the average of 19.51 million barrels per day in 2008. We have proven that when the price skyrocketed, we were able to live with less petroleum, but with prices more reasonable, our consumption will increase. What steps have we taken to prevent our being held captive to those high prices aga in?

Bill Gates recently showed his support for algae by investing $100 million in Sapphire Energy, one of our members. That company provided the algae for the recent test flight conducted by Continental Airlines. The preliminary results of that flight were better than expected, and there is no reason not to proceed with algae production. Interestingly, Sapphire is also working on algae as an alternative for automobile fuel.

Many other companies are starting up algae oil production plants across the United States, creating jobs and energy security for our country. In furthering its mission of fast-tracking commercialization of algae, our next quarterly forum will focus on equipment – in very basic terms, what is needed and what is already available.

Please let us know if you would be interested in presenting your equipment capabilities at our next quarterly conference, April 30-May 1, 2009, to assist the algae oil production and biomass industry.

Thank you,

National Algae Association, The Woodlands, Texas

Proposed Algae Equipment Manufacturers and Supply Channel Partner Presentations – April 2009

Algae is a source of biomass that can produce many types of biofuels, including biodiesel, ethanol, biocrude, jet fuel, and renewable diesel. Algae is a renewable fuel feedstock, does not affect the food channel and consumes C02. The byproduct biomass is used in cosmetics, pharmaceuticals, bio-plastics, and organic fertilizer. The National Algae Association, the first national trade association for the algae biofuels industry, brings algae companies and algae researchers from the US and around the world to exchange information to overcome technological hurdles.

The Department of Energy projects in its Energy Information Administration/Short-Term Energy Outlook - January 2009 that US petroleum consumption will be 19.12 million barrels per day in 2009, increasing to 19.28 million barrels per day in 2010. This is down from the average of 19.51 million barrels per day in 2008. We have proven that when the price skyrocketed, we were able to live with less petroleum, but with prices more reasonable, our consumption will increase. What steps have we taken to prevent our being held captive to those high prices aga in?

Bill Gates recently showed his support for algae by investing $100 million in Sapphire Energy, one of our members. That company provided the algae for the recent test flight conducted by Continental Airlines. The preliminary results of that flight were better than expected, and there is no reason not to proceed with algae production. Interestingly, Sapphire is also working on algae as an alternative for automobile fuel.

Many other companies are starting up algae oil production plants across the United States, creating jobs and energy security for our country. In furthering its mission of fast-tracking commercialization of algae, our next quarterly forum will focus on equipment – in very basic terms, what is needed and what is already available.

Please let us know if you would be interested in presenting your equipment capabilities at our next quarterly conference, April 30-May 1, 2009, to assist the algae oil production and biomass industry.

Thank you,

National Algae Association, The Woodlands, Texas

www.nationalalgaeassociation.com

Please note: This Organisation still exists

...................................................................

Future of fuel in our forests

STUART INNES

The Advertiser (Adelaide, Australia) 02-25-2009

The Advertiser (Adelaide, Australia) 02-25-2009

Future of fuel in our forests

Byline: STUART INNES Edition: 1 State

Section: News

SOUTH Australia is to play a big role in producing ethanol for fuel which eventually will replace up to a quarter of the petrol used in cars, a GM Holden expert says.

Forests, including pine plantations in the South-East and even Mallee scrub saltbush, would make ideal sources of raw material for ethanol, director of energy and environment for GM Holden, Richard Marshall, said yesterday.

He confirmed an E85 version of the Commodore - able to run on up to 85 per cent ethanol/15 per cent petrol - would come off the Holden production line at Elizabeth as early as next year.

Ethanol is made of plant and vegetable matter, which can be regrown. As such, it is renewable, unlike petrol and diesel.

Mr Marshall was commenting on findings of a nine-month U.S. study by Sandia National Laboratories and General Motors Corporation.

That says plant and forestry waste and dedicated energy crops could replace nearly a third of U.S. gasoline use by 2030.

Mr Marshall said in Australia, where ethanol is in a fledgling state, raw stock mainly would come from sugar cane and wheat starch.

"There would be no food for fuel," he said of any fear growing plants for fuel would be at the cost of crops for food. Other sources would be waste material, such as plantation timber, and "more specialised crops" from such dry areas as Mallee saltbush.

A tax and cost incentive strategy from governments, as called for in the U.S. study, would be needed to make the final product attractive.

Mr Marshall estimated Australia could have 20 to 25 per cent of petroleum use replaced by ethanol at a viable price.

............................................

SOUTH AUSTRALIAN RESEARCH AND DEVELOPMENT INSTITUTE (SARDI)

ADELAIDE, SOUTH AUSTRALIA

Biofuels

SARDI is developing a research capability in biofuels with an initial focus on biodiesel.

The Australian Government has set a target for the production of 350 million litres (ML) of biofuels per annum by 2010, representing 1% of total Australian transport and fuel consumption (currently around 35 000 ML).

The biodiesel industry is already a significant force in the United States and Europe and is rapidly emerging as a new industry sector in Australia, with approximately 450 ML of production capacity coming on stream in 2006, up from only 10 ML in 2004.

Australian Renewable Fuels (ARF) has commissioned its first biodiesel production plant in South Australia and its second plant in Western Australia will be opened in June 2006. Using waste oil and tallow as feedstock, these plants will enable ARF to supply up to 2% of the diesel market in those States. ARF’s long-term objective is to supply up to 8% of the South Australian and Western Australian markets and 5% of the Australian markets.

To do this will require enhanced varieties in crop-based feedstocks and the development of additional novel feedstocks (e.g. microalgae) for biodiesel production. It is proposed that research funded through SARDI will be pivotal in addressing this need.

Through research and innovation, Australia could become an international leader in biodiesel systems and technologies thus underpinning emerging manufacturing and primary production industries.

The Sustainable Systems Research Division, led by the Chief Rob Thomas, has developed a new program focusing on Biofuels (with an initial focus on Biodiesel). This program is led by A/Principal Scientist Dr Eric Capelle. The primary role of the program is to use existing and new SARDI expertise and infrastructure to research and develop feedstocks for biofuel production. Reliable, affordable sources of feedstock are needed to underpin the rapidly developing Biofuels industry.

SARDI has a strategic relationship with Australian Renewable Fuels (ARF). This company was recently listed on the Australian Stock Exchange. Its strategy is to become the leader in biodiesel production in Australia. ARF’s first 45 000 million litre per annum production plant has been built in Adelaide and will initially use tallow as feedstock. ARF intends to expand its production capacity to 220 000 million litres per annum and to do that it will need new sources of feedstock. ARF has engaged SARDI to research and develop new (and improved) feedstocks from crops,

microalgae and other sources.

In order to establish this position, SARDI has restructured its research groups. Under the new structure, the Biofuels group will include two subprograms – breeding and microalgae.

SARDI will use current breeding and farming systems capabilities to evaluate and develop canola and mustard varieties specifically tailored to biodiesel production. Some of these varieties will be targeted to cultivation in low-rainfall areas of the state, providing farmers with more crop choice in rotations.

The SARDI aquatic science research capability will also be used to select and develop microalgae as a source of oil for biodiesel. Studies show that algae can produce up to 60% of their biomass in the form of oil. Because the cells grow in aqueous suspension where they have more efficient access to water, CO2 and dissolved nutrients, microalgae are capable of producing large amounts of oil in either pond culture of bioreactors. Both technologies will be researched at SARDI.

Projects related to Biofuels

Sustainable production of biodiesel from microalgae

Collaborators:

|

|

Objectives:

|

|

Budget:

|

|

Leader:

|

|

Evaluation and development of new crops as feedstocks for biodiesel production

Collaborators:

|

|

Objectives:

|

|

Budget:

|

|

Leader:

|

|

New Biofuels Research Infrastructure

The SARDI Biofuels group has been successful in winning funds of A$5 million to develop a National Photobioreactor Facility in South Australia, based at SARDI’s West Beach site. This will be one of two pilot scale facilities in Australia for developing novel biofuel production technologies and is supported by the National Collaborative Research Infrastructure Strategy (NCRIS). The NCRIS program is run by the Commonwealth Government and requires State Government co-investment.

The NCRIS facilities will create new research infrastructure focused on developing new technologies for producing biodiesel and bioethanol from non-food biomass, based on models which productively utilise the whole of the biomass feedstock. The facility at SARDI will enable lab-scale photobioreactor results to be validated at pilot and demonstration-scale, an essential step in taking new biofuel feedstock technologies towards full commercialisation.

...................

SARDI

NCRIS Photobioreactor Facility

Background

The new $5 million National Collaborative Research Infrastructure Strategy (NCRIS) National Photobioreactor Facility is located at the South Australian Research and Development Institute’s (SARDI), Aquatic Sciences facility at West Beach, Adelaide. The NCRIS facility provides the capability for clients to research microalgal growth in experimental photobioreactors and raceways and in real time, to manipulate and monitor the system’s operational parameters and algal photophysiological parameters whilst optimising the production of algal biomass and overall lipid yield.

Microalgal culture systems

Three systems are available:

- The pilot-scale photobioreactor system comprises a 3.5m3 Algelink Solutions, tubular bioreactor, which is illuminated with natural sunlight. A regulated automated injection of nutrients (particularly inorganic sources of nitrogen and phosphorus) and carbon dioxide (dissolved in the water) can be achieved.

- Three 20m2 (10 x 2 x 0.5m) raceway ponds.

- A controlled environment room where manipulative small-scale physiological experiments can be carried out in a 15L Applikon Autoclavable photobioreactor or flasks

The facility also provides a range of microalgal harvesting systems (e.g. centrifuges) and facilities to store and process the harvested algal biomass.

Analytical capability

The physiological monitoring system comprises a state of the art relocatable laboratory with instrumentation selected to monitor the health and productivity of the microalgae and environment of the culture system and the water quality parameters of the growth medium.

There are three separate laboratories which in general house the:

- analytical microalgal photophysiological equipment;

- equipment to isolate and maintain pure cultures of microalgae; and

Laboratory equipment includes:

- Spectrophotometer (Shimadzu UV-1700) to determine cell densities and the grow rates of the microalgae cultures.

- Spectrofluorometer (Hitachi) to determine the lipid and chlorophyll content in algal media.

- Automatic Soxhlet system (Gerhardt Soxtherm) to extract the lipids out of the microalgae or other oil containing organisms to determine the oil content.

- Nutrient analyser (Aquakem 200cd) to determines the nutrient concentrations in the growing media. It also could be used to adjust the output of the automated nutrient injection system.

- Fluorescent microscope (Olympus BX-61) to enable quantification of intracellular lipid production and the general health of the microalgal cells.

- Flow cytometer (Beckman-coulter Cell lab Quanta SC) to simultaneously measures electronic volume, side scatter and three fluorescent colours to provide unsurpassed population resolution and accurate cell counting. Additionally it provides information on lipid and chlorophyll content, plus the health of the cells.

- Liquid Scintillation Counter (Perkin Elmer) to measure overall productivity, carbon uptake rates and to trace lipid and carbon pathways.

- Rotovap including classic Soxhlet extraction unit (Buchi R210, Buchi V700 and V850) to remove the remaining solvents after the hot soxhlet extraction unit. Or provide an all in one step oil cold soxhlet extraction method.

- TOC / TN Analyser (Analytic Jenna) to analyse the total organic carbon and total bound nitrogen in liquid and solid samples.

- Phytoplankton physiology analyser to evaluate photosynthetic yield in response to environmental conditions.

- Gas Chromatography system to determine the ester profile of algal oil and will also determine the conversion of the oil into biodiesel.

- HPLC system to determine the phospholipids and sterol glucosides in the microalgal oil and used for protein anlyses.

- Gel Electrophoresis to identify and quantitate the proteins present in the algal samples.

- Freeze Dryer to process and stabilize harvested algal samples.

- Incubator for carbon uptake analyses

A range of additional laboratory equipment exists, including:

- Dishwasher (Miele G7804)

- Light meter (Li-cor LI-1400)

- Moisture balance (Mettler-Toledo HG63)

- Balance 3100g (Mettler-Toledo PB3001-L)

- Micro-balance (Mettler-Toledo AB204-S/FACT)

- Fume cupboard (Dynasafe MK3)

- Laboratory fridge (Thermoline scientific)

- Laboratory freezer (Thermoline scientific)

- Refrigerated centrifuge (Eppendorf 5810 R)

- Millipore Elix 5 Reverse Osmosis system

- Autoclave (Hirayama HV-110L)

- Flammable storage cabinet (Safe-T-Store 250L)

- Corrosives storage cabinet (Storemasta 80L)

- Heater - stirrer (VELP)

- Platform mixer (Ratek)

- Ultrasonic cleaner (Unisonics)

- Oven (Invitro UNB500)

- Laminar flow cabinet (Clyde Apac HWS Series II)

Service and costs

We offer access to quality facilities, technical expertise and advanced equipment at a subsidised rate for eligible researchers. The overall objectives are to encourage collaboration and reduce duplication of research infrastructure, nationally.

NCRIS provides the technical expertise to operate and conduct analyses at the request of customers or provide customer with the training they require to undertake the work themselves.

A comprehensive cost structure is under development and will be made available in the near future.

How to get access?

Researchers wishing to apply for access to the facilities should contact the Ausbiotech NCRIS Program Manager or contact the respective NCRIS Photobioreactor Facility Manager.

Contact

Nicole Bleasdale

NCRIS Program Manager

AusBiotech

Level 1, 322 Glenferrie Road, Malvern VIC 3144

Phone +61 3 9828 1416

Fax +61 3 9824 5188

nbleasdale@ausbiotech.org

http://www.ausbiotech.org/

http://www.ncrisbiofuels.org/

NCRIS Program Manager

AusBiotech

Level 1, 322 Glenferrie Road, Malvern VIC 3144

Phone +61 3 9828 1416

Fax +61 3 9824 5188

nbleasdale@ausbiotech.org

http://www.ausbiotech.org/

http://www.ncrisbiofuels.org/

Dr Eric Capelle

NCRIS Photobioreactor Facility Manager

South Australian Research and Development Institute

SA Aquatic Science Centre

2 Hamra Avenue, West Beach SA 5024

Phone +61 8 8207 5369

Fax +61 8 8207 5390

Mobile 0422 004 771

capelle.eric@saugov.sa.gov.au

http://www.ncrisbiofuels.org/

NCRIS Photobioreactor Facility Manager

South Australian Research and Development Institute

SA Aquatic Science Centre

2 Hamra Avenue, West Beach SA 5024

Phone +61 8 8207 5369

Fax +61 8 8207 5390

Mobile 0422 004 771

capelle.eric@saugov.sa.gov.au

http://www.ncrisbiofuels.org/

Staff

Dr Eric Capelle - NCRIS Photobioreactor Facility Manager

Eric holds a bachelors degree in Organic Chemistry and Analytical Chemistry and was awarded a doctorate in applied science by the University of South Australia in 2006. He was the laboratory and quality assurance manager responsible for the design, construction and operation of the Australian Renewable Fuels analytical laboratories (ASG Analytik) in Adelaide and Picton, WA. He has more than 20 years experience in quality assurance laboratories for materials manufacturing plants, as well as several years of postgraduate study in this field. He has vast experience in analytical chemistry and quality control and standards for biodiesel in Australia.Barbara Rone-Clarke - NCRIS Laboratory Manager

Barbara holds a BSc (Hons) degree from Birkbeck College, University of London. Before joining NCRIS she was Quality Control Manager for Novozymes Biopharma. She has over 12 years experience managing quality control laboratories, both in Australia and New Zealand in a biopharmaceutical/biotechnology environment. Barbara also has considerable experience analysing oil, gas and water samples having worked in the petroleum industry in the UK and the geothermal industry in Indonesia.

Maria-Eugenia Segade-Enrique - NCRIS Technical Officer

Maria-Eugenia holds a Licenciatura en Ciencias Biologicas (M.Sc. equivalent) from the University of Buenos Aires, Argentina. Before coming to Australia, she was working for the Invertebrate laboratory of the Argentine Museum of Natural Sciences. Since arriving in Australia, she has worked for the Southern Seas Ecology Lab, Adelaide University, conducting chlorophyll analysis and processing water samples as well as rearing animals in aquaria. From January 2008 until starting with NCRIS she worked for the Environment and Ecology and Wild Fisheries science program areas at SARDI Aquatic Sciences. She has more than 6 years experience working in a variety of laboratory environments

Maria-Eugenia holds a Licenciatura en Ciencias Biologicas (M.Sc. equivalent) from the University of Buenos Aires, Argentina. Before coming to Australia, she was working for the Invertebrate laboratory of the Argentine Museum of Natural Sciences. Since arriving in Australia, she has worked for the Southern Seas Ecology Lab, Adelaide University, conducting chlorophyll analysis and processing water samples as well as rearing animals in aquaria. From January 2008 until starting with NCRIS she worked for the Environment and Ecology and Wild Fisheries science program areas at SARDI Aquatic Sciences. She has more than 6 years experience working in a variety of laboratory environments

....................................

....................................

Algaculture

From Wikipedia, the free encyclopedia

Algaculture is a form of aquaculture involving the farming of species of algae.

The majority of algae that are intentionally cultivated fall into the category of microalgae (also referred to as phytoplankton, microphytes, or planktonic algae). Macroalgae, commonly known as seaweed, also have many commercial and industrial uses, but due to their size and the specific requirements of the environment in which they need to grow, they do not lend themselves as readily to cultivation (this may change, however, with the advent of newer seaweed cultivators, which are basically algae scrubbers using upflowing air bubbles in small containers).

Commercial and industrial algae cultivation has numerous uses, including production of food ingredients such as omega-3 fatty acids or natural food colorants and dyes, food, fertilizer, bioplastics, chemical feedstock (raw material), pharmaceuticals, and algal fuel, and can also be used as a means of pollution control.

The majority of algae that are intentionally cultivated fall into the category of microalgae (also referred to as phytoplankton, microphytes, or planktonic algae). Macroalgae, commonly known as seaweed, also have many commercial and industrial uses, but due to their size and the specific requirements of the environment in which they need to grow, they do not lend themselves as readily to cultivation (this may change, however, with the advent of newer seaweed cultivators, which are basically algae scrubbers using upflowing air bubbles in small containers).

Commercial and industrial algae cultivation has numerous uses, including production of food ingredients such as omega-3 fatty acids or natural food colorants and dyes, food, fertilizer, bioplastics, chemical feedstock (raw material), pharmaceuticals, and algal fuel, and can also be used as a means of pollution control.

Contents

Growing, harvesting, and processing algae

Monoculture

This section does not cite any sources. (October 2013) (Learn how and when to remove this template message)

|

A common method of obtaining pure cultures is serial dilution. Cultivators dilute either a wild sample or a lab sample containing the desired algae with filtered water and introduce small aliquots (measures of this solution) into a large number of small growing containers. Dilution follows a microscopic examination of the source culture that predicts that a few of the growing containers contain a single cell of the desired species. Following a suitable period on a light table, cultivators again use the microscope to identify containers to start larger cultures.

Another approach is to use a special medium which excludes other organisms, including invasive algae. For example, Dunaliella is a commonly grown genus of microalgae which flourishes in extremely salty water that few other organisms can tolerate.

Alternatively, mixed algae cultures can work well for larval mollusks. First, the cultivator filters the sea water to remove algae which are too large for the larvae to eat. Next, the cultivator adds nutrients and possibly aerates the result. After one or two days in a greenhouse or outdoors, the resulting thin soup of mixed algae is ready for the larvae. An advantage of this method is low maintenance.

Growing algae

Microalgae is used culture brine shrimp,to which produce dormant eggs (pictured). The eggs can then be hatched on demand and fed to cultured fish larvae and crustaceans.

Temperature

The water must be in a temperature range that will support the specific algal species being grown mostly between 15˚C and 35˚C.Light and mixing

In a typical algal-cultivation system, such as an open pond, light only penetrates the top 3 to 4 inches (76–102 mm) of the water, though this depends on the algae density. As the algae grow and multiply, the culture becomes so dense that it blocks light from reaching deeper into the water. Direct sunlight is too strong for most algae, which can use only about 1⁄10 the amount of light they receive from direct sunlight; however, exposing an algae culture to direct sunlight (rather than shading it) is often the best course for strong growth, as the algae underneath the surface is able to utilize more of the less intestine light created from the shade of the algae above.To use deeper ponds, growers agitate the water, circulating the algae so that it does not remain on the surface. Paddle wheels can stir the water and compressed air coming from the bottom lifts algae from the lower regions. Agitation also helps prevent over-exposure to the sun.

Another means of supplying light is to place the light in the system. Glow plates made from sheets of plastic or glass and placed within the tank offer precise control over light intensity, and distribute it more evenly. They are seldom used, however, due to high cost.

Odor and oxygen

The odor associated with bogs, swamps, indeed any stagnant waters, can be due to oxygen depletion caused by the decay of deceased algal blooms. Under anoxic conditions, the bacteria inhabiting algae cultures break down the organic material and produce hydrogen sulfide and ammonia which causes the odor. This hypoxia often results in the death of aquatic animals. In a system where algae is intentionally cultivated, maintained, and harvested, neither eutrophication nor hypoxia are likely to occur.Some living algae and bacteria, also produce odorous chemicals, particularly certain (cyanobacteria) (previously classed as blue-green algae) such as Anabaena. The most well-known of these odor-causing chemicals are MIB (2-methylisoborneol) and geosmin. They give a musty or earthy odor that can be quite strong. Eventual death of the cyanobacteria releases additional gas that is trapped in the cells. These chemicals are detectable at very low levels, in the parts per billion range, and are responsible for many "taste and odor" issues in drinking water treatment and distribution.[2] Cyanobacteria can also produce chemical toxins that have been a problem in drinking water.

Nutrients

Nutrients such as nitrogen (N), phosphorus (P), and potassium (K) serve as fertilizer for algae, and are generally necessary for growth. Silica and iron, as well as several trace elements, may also be considered important marine nutrients as the lack of one can limit the growth of, or productivity in, a given area. Carbon dioxide is also essential; usually an input of CO2 is required for fast-paced algal growth. These elements must be dissolved into the water, in bio-available forms, for algae to grow.Pond and bioreactor cultivation methods

Algae can be cultured in open ponds (such as raceway-type ponds and lakes) and photobioreactors. Raceway ponds may be less expensive.[citation needed]Open ponds

Raceway pond used to cultivate microalgae. The water is kept in constant motion with a powered paddle wheel.

Open pond systems are cheaper to construct, at the minimum requiring only a trench or pond. Large ponds have the largest production capacities relative to other systems of comparable cost. Also, open pond cultivation can exploit unusual conditions that suit only specific algae. For instance, Dunaliella salina grow in extremely salty water; these unusual media exclude other types of organisms, allowing the growth of pure cultures in open ponds. Open culture can also work if there is a system of harvesting only the desired algae, or if the ponds are frequently re-inoculated before invasive organisms can multiply significantly. The latter approach is frequently employed by Chlorella farmers, as the growth conditions for Chlorella do not exclude competing algae.

The former approach can be employed in the case of some chain diatoms since they can be filtered from a stream of water flowing through an outflow pipe. A "pillow case" of a fine mesh cloth is tied over the outflow pipe allowing other algae to escape. The chain diatoms are held in the bag and feed shrimp larvae (in Eastern hatcheries) and inoculate new tanks or ponds.

Enclosing a pond with a transparent or translucent barrier effectively turns it into a greenhouse. This solves many of the problems associated with an open system. It allows more species to be grown, it allows the species that are being grown to stay dominant, and it extends the growing season – if heated, the pond can produce year round. Open race way ponds were used for removal of lead using live Spirulina (Arthospira) sp.[3]

Photobioreactors

Algae can also be grown in a photobioreactor (PBR). A PBR is a bioreactor which incorporates a light source. Virtually any translucent container could be called a PBR; however, the term is more commonly used to define a closed system, as opposed to an open tank or pond.Because PBR systems are closed, the cultivator must provide all nutrients, including CO

2.

A PBR can operate in "batch mode", which involves restocking the reactor after each harvest, but it is also possible to grow and harvest continuously. Continuous operation requires precise control of all elements to prevent immediate collapse. The grower provides sterilized water, nutrients, air, and carbon dioxide at the correct rates. This allows the reactor to operate for long periods. An advantage is that algae that grows in the "log phase" is generally of higher nutrient content than old "senescent" algae. Algal culture is the culturing of algae in ponds or other resources. Maximum productivity occurs when the "exchange rate" (time to exchange one volume of liquid) is equal to the "doubling time" (in mass or volume) of the algae.

Different types of PBRs include:

- Tanks

- Polyethylene sleeves or bags

- Glass or plastic tubes.

Harvesting

A seaweed farmer in Nusa Lembongan gathers edible seaweed that has grown on a rope.

Interrupting the carbon dioxide supply can cause algae to flocculate on its own, which is called "autoflocculation".

"Chitosan", a commercial flocculant, more commonly used for water purification, is far more expensive. The powdered shells of crustaceans are processed to acquire chitin, a polysaccharide found in the shells, from which chitosan is derived via de-acetylation. Water that is more brackish, or saline requires larger amounts of flocculant. Flocculation is often too expensive for large operations.

Alum and ferric chloride are other chemical flocculants.

In froth flotation, the cultivator aerates the water into a froth, and then skims the algae from the top.[5]

Ultrasound and other harvesting methods are currently under development.[6][7][8]

Oil extraction

Algae oils have a variety of commercial and industrial uses, and are extracted through a variety of methods. Estimates of the cost to extract oil from microalgae vary, but are likely to be around three times higher than that of extracting palm oil.[9]Physical extraction

In the first step of extraction, the oil must be separated from the rest of the algae. The simplest method is mechanical crushing. When algae is dried it retains its oil content, which then can be "pressed" out with an oil press. Different strains of algae warrant different methods of oil pressing, including the use of screw, expeller and piston. Many commercial manufacturers of vegetable oil use a combination of mechanical pressing and chemical solvents in extracting oil. This use is often also adopted for algal oil extraction.Osmotic shock is a sudden reduction in osmotic pressure, this can cause cells in a solution to rupture. Osmotic shock is sometimes used to release cellular components, such as oil.

Ultrasonic extraction, a branch of sonochemistry, can greatly accelerate extraction processes. Using an ultrasonic reactor, ultrasonic waves are used to create cavitation bubbles in a solvent material. When these bubbles collapse near the cell walls, the resulting shock waves and liquid jets cause those cells walls to break and release their contents into a solvent.[10] Ultrasonication can enhance basic enzymatic extraction. The combination "sonoenzymatic treatment" accelerates extraction and increases yields.[11]

Chemical extraction

Chemical solvents are often used in the extraction of the oils. The downside to using solvents for oil extraction are the dangers involved in working with the chemicals. Care must be taken to avoid exposure to vapors and skin contact, either of which can cause serious health damage. Chemical solvents also present an explosion hazard.[12]A common choice of chemical solvent is hexane, which is widely used in the food industry and is relatively inexpensive. Benzene and ether can also separate oil. Benzene is classified as a carcinogen.

Another method of chemical solvent extraction is Soxhlet extraction. In this method, oils from the algae are extracted through repeated washing, or percolation, with an organic solvent such as hexane or petroleum ether, under reflux in a special glassware.[13] The value of this technique is that the solvent is reused for each cycle.

Enzymatic extraction uses enzymes to degrade the cell walls with water acting as the solvent. This makes fractionation of the oil much easier. The costs of this extraction process are estimated to be much greater than hexane extraction.[14] The enzymatic extraction can be supported by ultrasonication. The combination "sonoenzymatic treatment" causes faster extraction and higher oil yields.[11]

Supercritical CO2 can also be used as a solvent. In this method, CO2 is liquefied under pressure and heated to the point that it becomes supercritical (having properties of both a liquid and a gas), allowing it to act as a solvent.[15][16]

Other methods are still being developed, including ones to extract specific types of oils, such as those with a high production of long-chain highly unsaturated fatty acids.[6][7]

Algal culture collections

Specific algal strains can be acquired from algal culture collections, with over 500 culture collections registered with the World Federation for Culture Collections.[17]Uses of algae

Dulse is one of many edible algae.

Food

Several species of algae are raised for food.- Purple laver (Porphyra) is perhaps the most widely domesticated marine algae.[18] In Asia it is used in nori (Japan) and gim (Korea). In Wales, it is used in laverbread, a traditional food, and in Ireland it is collected and made into a jelly by stewing or boiling. Preparation also can involve frying or heating the fronds with a little water and beating with a fork to produce a pinkish jelly. Harvesting also occurs along the west coast of North America, and in Hawaii and New Zealand.

- Dulse (Palmaria palmata) is a red species sold in Ireland and Atlantic Canada. It is eaten raw, fresh, dried, or cooked like spinach.

- Spirulina (Arthrospira platensis) is a blue-green microalgae with a long history as a food source in East Africa and pre-colonial Mexico. Spirulina is high in protein and other nutrients, finding use as a food supplement and for malnutrition. Spirulina thrives in open systems and commercial growers have found it well-suited to cultivation. One of the largest production sites is Lake Texcoco in central Mexico.[19] The plants produce a variety of nutrients and high amounts of protein. Spirulina is often used commercially as a nutritional supplement.[20][21]

- Chlorella, another popular microalgae, has similar nutrition to spirulina. Chlorella is very popular in Japan. It is also used as a nutritional supplement with possible effects on metabolic rate.[22] Some allege that Chlorella can reduce mercury levels in humans (supposedly by chelation of the mercury to the cell wall of the organism).[23]

- Irish moss (Chondrus crispus), often confused with Mastocarpus stellatus, is the source of carrageenan, which is used as a stiffening agent in instant puddings, sauces, and dairy products such as ice cream. Irish moss is also used by beer brewers as a fining agent.

- Sea lettuce (Ulva lactuca), is used in Scotland where it is added to soups and salads.

- Dabberlocks or badderlocks (Alaria esculenta) is eaten either fresh or cooked in Greenland, Iceland, Scotland and Ireland.

- Aphanizomenon flos-aquae is a cyanobacteria similar to spirulina, which is used as a nutritional supplement.

- Extracts and oils from algae are also used as additives in various food products.[24] The plants also produce Omega-3 and Omega-6 fatty acids, which are commonly found in fish oils, and which have been shown to have positive health benefits.[25]

- Sargassum species are an important group of seaweeds. These algae have many phlorotannins.

- Cochayuyo (Durvillaea antarctica) is eaten in salads and ceviche in Peru and Chile.

Fertilizer and agar

For centuries seaweed has been used as fertilizer. It is also an excellent source of potassium for manufacture of potash and potassium nitrate.Both microalgae and macroalgae are used to make agar.[26][27][28]

Pollution control

With concern over global warming, new methods for the thorough and efficient capture of CO2 are being sought out. The carbon dioxide that a carbon-fuel burning plant produces can feed into open or closed algae systems, fixing the CO2 and accelerating algae growth. Untreated sewage can supply additional nutrients, thus turning two pollutants into valuable commodities.[29]Algae cultivation is under study for uranium/plutonium sequestration and purifying fertilizer runoff.

Energy production

Business, academia and governments are exploring the possibility of using algae to make gasoline, diesel and other fuels. Algae itself may be used as a biofuel, and additionally be used to create hydrogen. See Algae fuel.Other uses

Chlorella, particularly a transgenic strain which carries an extra mercury reductase gene, has been studied as an agent for environmental remediation due to its ability to reduce Hg2+ to the less toxic elemental mercury.[30]Cultivated algae serve many other purposes, including cosmetics,[31] animal feed,[31] bioplastic production, dyes and colorant production, chemical feedstock production, and pharmaceutical ingredients.

...................................................................................

Will the blight on our waterways be a new source of fuel

GREG KELTON , LOS ANGELES Travelling with the Premier

The Advertiser (Adelaide, Australia)

08-18-2009

08-18-2009

Will the blight on our waterways be a new source of fuel

Byline: GREG KELTON GREG KELTON, LOS ANGELES Travelling with the Premier

Edition: 1 State

Section: News

THE U.S. parent company of uranium producer Heathgate Resources has held talks with the State Government over developing a renewable energy fuel in South Australia - from algae.

Premier Mike Rann met for an hour yesterday with Neal Blue, the chief executive officer of General Atomics, which owns the Beverley uranium deposits in SA's Far North.

Byline: GREG KELTON GREG KELTON, LOS ANGELES Travelling with the Premier

Edition: 1 State

Section: News

THE U.S. parent company of uranium producer Heathgate Resources has held talks with the State Government over developing a renewable energy fuel in South Australia - from algae.

Premier Mike Rann met for an hour yesterday with Neal Blue, the chief executive officer of General Atomics, which owns the Beverley uranium deposits in SA's Far North.

Mr Rann said SA was now poised to become a national leader in refining biosynthetic fuels, with the potential to create thousands of jobs.

Mr Blue said his company was interested in developments in microalgal biofuels in SA because there was huge potential for their use in the future - especially in the aviation industry.

Mr Blue said at least one U.S. commercial airline had already tested biofuels in a passenger flight across America. He said SA was highly placed to develop algal fuels because of its high sunlight, brackish water and carbon dioxide.

Mr Rann said algal biofuel was attractive because of its relatively high oil yield and its efficiency in recycling carbon.

"It is estimated that replacing just 10 per cent of Australia's mineral diesel with biodiesel from microalgae would bring about a reduction of nearly 4 million tonnes of carbon dioxide emissions from fossil fuels," he said.

The Federal Government recently granted $2.7 million to an SA- based consortium to develop a pilot-scale biorefinery for sustainable microalgal biofuels and added products.

The pilot project - run by the Algal Fuels Consortium which includes the SA Research and Development Institute, Flinders University and Sancon Recycling - will be located at Torrens Island.

General Atomics is one of several companies including Boeing, Lockheed Martin and Caltex, which are interested in the development.

Mr Rann said biodiesel made from algae was considered by many to be more environmentally acceptable than some past-generation biofuels, such as those made from sugar cane or other food crops.

He said international companies were investing substantial amounts of money in biofuel research and development, with BP investing $500 million two years ago in a University of California project.

Mr Blue said biosynthetic fuels worked, it was now a matter of how cheaply it could be produced, which was where projects like the Algal Fuels Consortium were important. His company was already working on a U.S. Defence Department contract examining synthetic fuel options.

"SARDI have been doing independent work on this so it has been of interest to us to become involved in SA in respect of our own interests in biosynthetic fuels," Mr Blue said.

((C) Copyright Nationwide News Pty Limited)

..................................................................................................................................

Algae fuel

A conical flask of "green" jet fuel made from algae

The head of the Algal Biomass Organization stated in 2010 that algae fuel could reach price parity with oil in 2018 if granted production tax credits.[13] However, in 2013, Exxon Mobil Chairman and CEO Rex Tillerson said that after committing to spend up to $600 million over 10 years on development in a joint venture with J. Craig Venter's Synthetic Genomics in 2009, Exxon pulled back after four years (and $100 million) when it realized that algae fuel is "probably further" than 25 years away from commercial viability.[14] On the other hand, Solazyme,[15] Sapphire Energy,[16] and Algenol,[17] among others have begun commercial sale of algal biofuel in 2012 and 2013, and 2015, respectively. By 2017, most efforts had been abandoned or changed to other applications, with only a few remaining.[18]

Contents

- 1 History

- 2 Food supplementation

- 3 Fuels

- 4 Species

- 5 Nutrients and growth inputs

- 6 Cultivation

- 7 Fuel production

- 8 Nutrients

- 9 Environmental impact

- 10 Economic viability

- 11 Use of Byproducts

- 12 Advantages

- 13 Disadvantages

- 14 Research

- 15 International policies

- 16 Companies

- 17 See also

- 18 References

- 19 Further reading

- 20 External links

History

In 1942 Harder and Von Witsch were the first to propose that microalgae be grown as a source of lipids for food or fuel.[19][20] Following World War II, research began in the US,[21][22][23] Germany,[24] Japan,[25] England,[26] and Israel[27] on culturing techniques and engineering systems for growing microalgae on larger scales, particularly species in the genus Chlorella. Meanwhile, H. G. Aach showed that Chlorella pyrenoidosa could be induced via nitrogen starvation to accumulate as much as 70% of its dry weight as lipids.[28] Since the need for alternative transportation fuel had subsided after World War II, research at this time focused on culturing algae as a food source or, in some cases, for wastewater treatment.[29]Interest in the application of algae for biofuels was rekindled during the oil embargo and oil price surges of the 1970s, leading the US Department of Energy to initiate the Aquatic Species Program in 1978.[30] The Aquatic Species Program spent $25 million over 18 years with the goal of developing liquid transportation fuel from algae that would be price competitive with petroleum-derived fuels.[31] The research program focused on the cultivation of microalgae in open outdoor ponds, systems which are low in cost but vulnerable to environmental disturbances like temperature swings and biological invasions. 3,000 algal strains were collected from around the country and screened for desirable properties such as high productivity, lipid content, and thermal tolerance, and the most promising strains were included in the SERI microalgae collection at the Solar Energy Research Institute (SERI) in Golden, Colorado and used for further research.[31] Among the program's most significant findings were that rapid growth and high lipid production were "mutually exclusive", since the former required high nutrients and the latter required low nutrients.[31] The final report suggested that genetic engineering may be necessary to be able to overcome this and other natural limitations of algal strains, and that the ideal species might vary with place and season.[31] Although it was successfully demonstrated that large-scale production of algae for fuel in outdoor ponds was feasible, the program failed to do so at a cost that would be competitive with petroleum, especially as oil prices sank in the 1990s. Even in the best case scenario, it was estimated that unextracted algal oil would cost $59–186 per barrel,[31] while petroleum cost less than $20 per barrel in 1995.[30] Therefore, under budget pressure in 1996, the Aquatic Species Program was abandoned.[31]

Other contributions to algal biofuels research have come indirectly from projects focusing on different applications of algal cultures. For example, in the 1990s Japan's Research Institute of Innovative Technology for the Earth (RITE) implemented a research program with the goal of developing systems to fix CO

2 using microalgae.[32] Although the goal was not energy production, several studies produced by RITE demonstrated that algae could be grown using flue gas from power plants as a CO

2 source,[33][34] an important development for algal biofuel research. Other work focusing on harvesting hydrogen gas, methane, or ethanol from algae, as well as nutritional supplements and pharmaceutical compounds, has also helped inform research on biofuel production from algae.[29]

Following the disbanding of the Aquatic Species Program in 1996, there was a relative lull in algal biofuel research. Still, various projects were funded in the US by the Department of Energy, Department of Defense, National Science Foundation, Department of Agriculture, National Laboratories, state funding, and private funding, as well as in other countries.[30] More recently, rising oil prices in the 2000s spurred a revival of interest in algal biofuels and US federal funding has increased,[30] numerous research projects are being funded in Australia, New Zealand, Europe, the Middle East, and other parts of the world,[35] and a wave of private companies has entered the field[36] (see Companies). In November 2012, Solazyme and Propel Fuels made the first retail sales of algae-derived fuel,[15] and in March 2013 Sapphire Energy began commercial sales of algal biofuel to Tesoro.[16]

Food supplementation

Algal oil is used as a source of fatty acid supplementation in food products, as it contains mono- and polyunsaturated fats, in particular EPA and DHA.[37] Its DHA content is roughly equivalent to that of salmon based fish oil.[38][39]Fuels

Algae can be converted into various types of fuels, depending on the technique and the part of the cells used. The lipid, or oily part of the algae biomass can be extracted and converted into biodiesel through a process similar to that used for any other vegetable oil, or converted in a refinery into "drop-in" replacements for petroleum-based fuels. Alternatively or following lipid extraction, the carbohydrate content of algae can be fermented into bioethanol or butanol fuel.[40]Biodiesel

Biodiesel is a diesel fuel derived from animal or plant lipids (oils and fats). Studies have shown that some species of algae can produce 60% or more of their dry weight in the form of oil.[28][31][41][42][43] Because the cells grow in aqueous suspension, where they have more efficient access to water, CO2 and dissolved nutrients, microalgae are capable of producing large amounts of biomass and usable oil in either high rate algal ponds or photobioreactors. This oil can then be turned into biodiesel which could be sold for use in automobiles. Regional production of microalgae and processing into biofuels will provide economic benefits to rural communities.[44]

As they do not have to produce structural compounds such as cellulose for leaves, stems, or roots, and because they can be grown floating in a rich nutritional medium, microalgae can have faster growth rates than terrestrial crops. Also, they can convert a much higher fraction of their biomass to oil than conventional crops, e.g. 60% versus 2-3% for soybeans.[41] The per unit area yield of oil from algae is estimated to be from 58,700 to 136,900 L/ha/year, depending on lipid content, which is 10 to 23 times as high as the next highest yielding crop, oil palm, at 5 950 L/ha/year.[45]

The U.S. Department of Energy's Aquatic Species Program, 1978–1996, focused on biodiesel from microalgae. The final report suggested that biodiesel could be the only viable method by which to produce enough fuel to replace current world diesel usage.[46] If algae-derived biodiesel were to replace the annual global production of 1.1bn tons of conventional diesel then a land mass of 57.3 million hectares would be required, which would be highly favorable compared to other biofuels.[47]

Biobutanol

Butanol can be made from algae or diatoms using only a solar powered biorefinery. This fuel has an energy density 10% less than gasoline, and greater than that of either ethanol or methanol. In most gasoline engines, butanol can be used in place of gasoline with no modifications. In several tests, butanol consumption is similar to that of gasoline, and when blended with gasoline, provides better performance and corrosion resistance than that of ethanol or E85.[48]The green waste left over from the algae oil extraction can be used to produce butanol. In addition, it has been shown that macroalgae (seaweeds) can be fermented by Clostridia genus bacteria to butanol and other solvents.[49]

Biogasoline

Biogasoline is gasoline produced from biomass. Like traditionally produced gasoline, it contains between 6 (hexane) and 12 (dodecane) carbon atoms per molecule and can be used in internal-combustion engines.[50]Methane

Methane,[51] the main constituent of natural gas can be produced from algae in various methods, namely gasification, pyrolysis and anaerobic digestion. In gasification and pyrolysis methods methane is extracted under high temperature and pressure. Anaerobic digestion[52] is a straightforward method involved in decomposition of algae into simple components then transforming it into fatty acids using microbes like acidogenic bacteria followed by removing any solid particles and finally adding methanogenic bacteria to release a gas mixture containing methane. A number of studies have successfully shown that biomass from microalgae can be converted into biogas via anaerobic digestion.[53][54][55][56][57] Therefore, in order to improve the overall energy balance of microalgae cultivation operations, it has been proposed to recover the energy contained in waste biomass via anaerobic digestion to methane for generating electricity.[58]Ethanol

The Algenol system which is being commercialized by BioFields in Puerto Libertad, Sonora, Mexico utilizes seawater and industrial exhaust to produce ethanol. Porphyridium cruentum also have shown to be potentially suitable for ethanol production due to its capacity for accumulating large amount of carbohydrates.[59]Green diesel

Algae can be used to produce 'green diesel' (also known as renewable diesel, hydrotreating vegetable oil[60] or hydrogen-derived renewable diesel)[61] through a hydrotreating refinery process that breaks molecules down into shorter hydrocarbon chains used in diesel engines.[60][62] It has the same chemical properties as petroleum-based diesel[60] meaning that it does not require new engines, pipelines or infrastructure to distribute and use. It has yet to be produced at a cost that is competitive with petroleum.[61] While hydrotreating is currently the most common pathway to produce fuel-like hydrocarbons via decarboxylation/decarbonylation, there is an alternative process offering a number of important advantages over hydrotreating. In this regard, the work of Crocker et al.[63] and Lercher et al.[64] is particularly noteworthy. For oil refining, research is underway for catalytic conversion of renewable fuels by decarboxylation.[65] As the oxygen is present in crude oil at rather low levels, of the order of 0.5%, deoxygenation in petroleum refining is not of much concern, and no catalysts are specifically formulated for oxygenates hydrotreating. Hence, one of the critical technical challenges to make the hydrodeoxygenation of algae oil process economically feasible is related to the research and development of effective catalysts.[66][67]Jet fuel

Rising jet fuel prices are putting severe pressure on airline companies,[68] creating an incentive for algal jet fuel research. The International Air Transport Association, for example, supports research, development and deployment of algal fuels. IATA's goal is for its members to be using 10% alternative fuels by 2017.[69]Trials have been carried with aviation biofuel by Air New Zealand,[70] Lufthansa, and Virgin Airlines.[71]

In February 2010, the Defense Advanced Research Projects Agency announced that the U.S. military was about to begin large-scale oil production from algal ponds into jet fuel. After extraction at a cost of $2 per gallon, the oil will be refined at less than $3 a gallon. A larger-scale refining operation, producing 50 million gallons a year, is expected to go into production in 2013, with the possibility of lower per gallon costs so that algae-based fuel would be competitive with fossil fuels. The projects, run by the companies SAIC and General Atomics, are expected to produce 1,000 gallons of oil per acre per year from algal ponds.[72]

Species

Research into algae for the mass-production of oil focuses mainly on microalgae (organisms capable of photosynthesis that are less than 0.4 mm in diameter, including the diatoms and cyanobacteria) as opposed to macroalgae, such as seaweed. The preference for microalgae has come about due largely to their less complex structure, fast growth rates, and high oil-content (for some species). However, some research is being done into using seaweeds for biofuels, probably due to the high availability of this resource.[73][74]As of 2012 researchers across various locations worldwide have started investigating the following species for their suitability as a mass oil-producers:[75][76][77]

- Botryococcus braunii

- Chlorella

- Dunaliella tertiolecta

- Gracilaria

- Pleurochrysis carterae (also called CCMP647).[78]

- Sargassum, with 10 times the output volume of Gracilaria.[79]

- Ankistrodesmus TR-87: 28–40% dry weight

- Botryococcus braunii: 29–75% dw

- Chlorella sp.: 29%dw

- Chlorella protothecoides(autotrophic/ heterothrophic): 15–55% dw

- Crypthecodinium cohnii: 20%dw

- Cyclotella DI- 35: 42%dw

- Dunaliella tertiolecta : 36–42%dw

- Hantzschia DI-160: 66%dw

- Nannochloris: 31(6–63)%dw

- Nannochloropsis : 46(31–68)%dw

- Neochloris oleoabundans: 35–54%dw

- Nitzschia TR-114: 28–50%dw

- Phaeodactylum tricornutum: 31%dw

- Scenedesmus TR-84: 45%dw

- Schizochytrium 50–77%dw[80]

- Stichococcus: 33(9–59)%dw

- Tetraselmis suecica: 15–32%dw

- Thalassiosira pseudonana: (21–31)%dw

Other species used include Clostridium saccharoperbutylacetonicum,[83] Sargassum, Glacilaria, Prymnesium parvum, and Euglena gracilis[84]

Nutrients and growth inputs

Light is what algae primarily need for growth as it is the most limiting factor. Many companies are investing for developing systems and technologies for providing artificial light. One of them is OriginOil that has developed a Helix BioReactorTM that features a rotating vertical shaft with low-energy lights arranged in a helix pattern.[85] Water temperature also influences the metabolic and reproductive rates of algae. Although most algae grow at low rate when the water temperature gets lower, the biomass of algal communities can get large due to the absence of grazing organisms.[85] The modest increases in water current velocity may also affect rates of algae growth since the rate of nutrient uptake and boundary layer diffusion increases with current velocity.[85]Other than light and water, phosphorus, nitrogen, and certain micronutrients are also useful and essential in growing algae. Nitrogen and phosphorus are the two most significant nutrients required for algal productivity, but other nutrients such as carbon and silica are additionally required.[86] Of the nutrients required, phosphorus is one of the most essential ones as it is used in numerous metabolic processes. The microalgae D. tertiolecta was analyzed to see which nutrient affects its growth the most.[87] The concentrations of phosphorus (P), iron (Fe), cobalt (Co), zinc (Zn), manganese (Mn) and molybdenum (Mo), magnesium (Mg), calcium (Ca), silicon (Si) and sulfur (S) concentrations were measured daily using inductively coupled plasma (ICP) analysis. Among all these elements being measured, phosphorus resulted in the most dramatic decrease, with a reduction of 84% over the course of the culture.[87] This result indicates that phosphorus, in the form of phosphate, is required in high amounts by all organisms for metabolism.

There are two enrichment media that have been extensively used to grow most species of algae: Walne medium and the Guillard's F/2 medium.[88] These commercially available nutrient solutions may reduce time for preparing all the nutrients required to grow algae. However, due to their complexity in the process of generation and high cost, they are not used for large-scale culture operations.[88] Therefore, enrichment media used for mass production of algae contain only the most important nutrients with agriculture-grade fertilizers rather than laboratory-grade fertilizers.[88]

Cultivation

Photobioreactor from glass tubes

Design of a race-way open pond commonly used for algal culture

Closed-loop system

The lack of equipment and structures needed to begin growing algae in large quantities has inhibited widespread mass-production of algae for biofuel production. Maximum use of existing agriculture processes and hardware is the goal.[91]Closed systems (not exposed to open air) avoid the problem of contamination by other organisms blown in by the air. The problem for a closed system is finding a cheap source of sterile CO

2. Several experimenters have found the CO

2 from a smokestack works well for growing algae.[92][93] For reasons of economy, some experts think that algae farming for biofuels will have to be done as part of cogeneration, where it can make use of waste heat and help soak up pollution.[94][95]

Photobioreactors

Most companies pursuing algae as a source of biofuels pump nutrient-rich water through plastic or borosilicate glass tubes (called "bioreactors" ) that are exposed to sunlight (and so-called photobioreactors or PBR).Running a PBR is more difficult than using an open pond, and costlier, but may provide a higher level of control and productivity.[42] In addition, a photobioreactor can be integrated into a closed loop cogeneration system much more easily than ponds or other methods.

Open pond

Raceway pond used for the cultivation of microalgae

Some open sewage-ponds trial production has taken place in Marlborough, New Zealand.[97]

Turf scrubber

2.5 acre ATS system, installed by Hydromentia on a farm creek in Florida

There are three major advantages of ATS over other systems. The first advantage is documented higher productivity over open pond systems.[102] The second is lower operating and fuel production costs. The third is the elimination of contamination issues due to the reliance on naturally occurring algae species. The projected costs for energy production in an ATS system are $0.75/kg, compared to a photobioreactor which would cost $3.50/kg.[100] Furthermore, due to the fact that the primary purpose of ATS is removing nutrients and pollutants out of water, and these costs have been shown to be lower than other methods of nutrient removal, this may incentivize the use of this technology for nutrient removal as the primary function, with biofuel production as an added benefit.[103]

Algae being harvested and dried from an ATS system

Fuel production

After harvesting the algae, the biomass is typically processed in a series of steps, which can differ based on the species and desired product; this is an active area of research[42] and also is the bottleneck of this technology: the cost of extraction is higher than those obtained. One of the solutions is to use filter feeders to "eat" them. Improved animals can provide both foods and fuels. An alternative method to extract the algae is to grow the algae with specific types of fungi. This causes bio-flocculation of the algae which allows for easier extraction.[104]Dehydration

Often, the algae is dehydrated, and then a solvent such as hexane is used to extract energy-rich compounds like triglycerides from the dried material.[1] Then, the extracted compounds can be processed into fuel using standard industrial procedures. For example, the extracted triglycerides are reacted with methanol to create biodiesel via transesterification.[1] The unique composition of fatty acids of each species influences the quality of the resulting biodiesel and thus must be taken into account when selecting algal species for feedstock.[42]Hydrothermal liquefaction

An alternative approach called Hydrothermal liquefaction employs a continuous process that subjects harvested wet algae to high temperatures and pressures—350 °C (662 °F) and 3,000 pounds per square inch (21,000 kPa).[105][106][107]Products include crude oil, which can be further refined into aviation fuel, gasoline, or diesel fuel using one or many upgrading processes.[108] The test process converted between 50 and 70 percent of the algae's carbon into fuel. Other outputs include clean water, fuel gas and nutrients such as nitrogen, phosphorus, and potassium.[105]

Nutrients

Nutrients like nitrogen (N), phosphorus (P), and potassium (K), are important for plant growth and are essential parts of fertilizer. Silica and iron, as well as several trace elements, may also be considered important marine nutrients as the lack of one can limit the growth of, or productivity in, an area.[109]Carbon dioxide

Bubbling CO2 through algal cultivation systems can greatly increase productivity and yield (up to a saturation point). Typically, about 1.8 tonnes of CO

2 will be utilised per tonne of algal biomass (dry) produced, though this varies with algae species.[110] The Glenturret Distillery in Perthshire, UK – home to The Famous Grouse Whisky – percolate CO

2 made during the whisky distillation through a microalgae bioreactor. Each tonne of microalgae absorbs two tonnes of CO

2. Scottish Bioenergy, who run the project, sell the microalgae as high value, protein-rich food for fisheries. In the future, they will use the algae residues to produce renewable energy through anaerobic digestion.[111]

Nitrogen

Nitrogen is a valuable substrate that can be utilized in algal growth. Various sources of nitrogen can be used as a nutrient for algae, with varying capacities. Nitrate was found to be the preferred source of nitrogen, in regards to amount of biomass grown. Urea is a readily available source that shows comparable results, making it an economical substitute for nitrogen source in large scale culturing of algae.[112] Despite the clear increase in growth in comparison to a nitrogen-less medium, it has been shown that alterations in nitrogen levels affect lipid content within the algal cells. In one study[113] nitrogen deprivation for 72 hours caused the total fatty acid content (on a per cell basis) to increase by 2.4-fold. 65% of the total fatty acids were esterified to triacylglycerides in oil bodies, when compared to the initial culture, indicating that the algal cells utilized de novo synthesis of fatty acids. It is vital for the lipid content in algal cells to be of high enough quantity, while maintaining adequate cell division times, so parameters that can maximize both are under investigation.Wastewater

A possible nutrient source is waste water from the treatment of sewage, agricultural, or flood plain run-off, all currently major pollutants and health risks. However, this waste water cannot feed algae directly and must first be processed by bacteria, through anaerobic digestion. If waste water is not processed before it reaches the algae, it will contaminate the algae in the reactor, and at the very least, kill much of the desired algae strain. In biogas facilities, organic waste is often converted to a mixture of carbon dioxide, methane, and organic fertilizer. Organic fertilizer that comes out of the digester is liquid, and nearly suitable for algae growth, but it must first be cleaned and sterilized.[114]The utilization of wastewater and ocean water instead of freshwater is strongly advocated due to the continuing depletion of freshwater resources. However, heavy metals, trace metals, and other contaminants in wastewater can decrease the ability of cells to produce lipids biosynthetically and also impact various other workings in the machinery of cells. The same is true for ocean water, but the contaminants are found in different concentrations. Thus, agricultural-grade fertilizer is the preferred source of nutrients, but heavy metals are again a problem, especially for strains of algae that are susceptible to these metals. In open pond systems the use of strains of algae that can deal with high concentrations of heavy metals could prevent other organisms from infesting these systems.[89] In some instances it has even been shown that strains of algae can remove over 90% of nickel and zinc from industrial wastewater in relatively short periods of time.[115]

Environmental impact

In comparison with terrestrial-based biofuel crops such as corn or soybeans, microalgal production results in a much less significant land footprint due to the higher oil productivity from the microalgae than all other oil crops.[116] Algae can also be grown on marginal lands useless for ordinary crops and with low conservation value, and can use water from salt aquifers that is not useful for agriculture or drinking.[94][117] Algae can also grow on the surface of the ocean in bags or floating screens.[118] Thus microalgae could provide a source of clean energy with little impact on the provisioning of adequate food and water or the conservation of biodiversity.[119] Algae cultivation also requires no external subsidies of insecticides or herbicides, removing any risk of generating associated pesticide waste streams. In addition, algal biofuels are much less toxic, and degrade far more readily than petroleum-based fuels.[120][121][122] However, due to the flammable nature of any combustible fuel, there is potential for some environmental hazards if ignited or spilled, as may occur in a train derailment or a pipeline leak.[123] This hazard is reduced compared to fossil fuels, due to the ability for algal biofuels to be produced in a much more localized manner, and due to the lower toxicity overall, but the hazard is still there nonetheless. Therefore, algal biofuels should be treated in a similar manner to petroleum fuels in transportation and use, with sufficient safety measures in place at all times.Studies have determined that replacing fossil fuels with renewable energy sources, such as biofuels, have the capability of reducing CO

2 emissions by up to 80%.[124] An algae-based system could capture approximately 80% of the CO

2 emitted from a power plant when sunlight is available. Although this CO

2 will later be released into the atmosphere when the fuel is burned, this CO

2 would have entered the atmosphere regardless.[117] The possibility of reducing total CO

2 emissions therefore lies in the prevention of the release of CO

2 from fossil fuels. Furthermore, compared to fuels like diesel and petroleum, and even compared to other sources of biofuels, the production and combustion of algal biofuel does not produce any sulfur oxides or nitrous oxides, and produces a reduced amount of carbon monoxide, unburned hydrocarbons, and reduced emission of other harmful pollutants.[125] Since terrestrial plant sources of biofuel production simply do not have the production capacity to meet current energy requirements, microalgae may be one of the only options to approach complete replacement of fossil fuels.

Microalgae production also includes the ability to use saline waste or waste CO